_副本-1.png)

1、Safety Factor

The main body of the steel structure is greater than 2.0, and the calculated pressure value of the vacuum system is determined at 60% vacuum degree.

2、Plate Overhang

As the figure below, it is calculated according to the plate overhang. To the thinnest plate of 0.8mm, its overhang is L=500mm. If the overhanging quantity in the plate handling exceeds the maximum allowable value, it will cause permanent deformation of the plate that cannot be recovered.

3、Pressure Warning

Vacuum pressure switch and vacuum lamp alarm unit are installed on the vacuum lift. When the following situations occur, it is recommended to deal with the equipment in time. The vacuum system pressure does not reach the set pressure value, or vacuum leakage occurs with the vacuum lamp change from green to red.

Each vacuum lift is equipped with one vacuum pressure switch:

It could visual display system vacuum pressure.

It could detect the system pressure automatically. When the digital display pressure below -58 kpa, vacuum light will change from green to red, the vacuum pump will automatically start. When the digital display pressure is greater than 66kpa, vacuum light will change from red to green and vacuum pump stop working automatically.

When the vacuum lift is handling, the operator should always observe the digital display pressure of the vacuum.

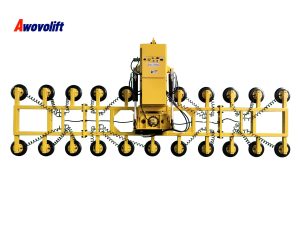

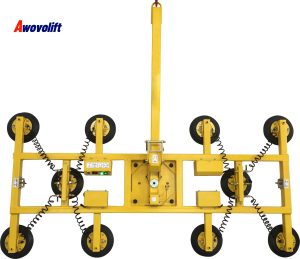

4、Each sucker is equipped with a manual ball valve to control the opening and closing, so as to ensure that the same equipment can be suitable for various specifications of the plates.

5、Each sucker rod is equipped with a spring, so that the plate can be better fit when it is uneven or curved. At the same time, the spring also plays a buffering role, it can make the sucker force uniformly, so as to ensure the safety of the vacuum lift.